The Importance of Regular Slitter Rewinder Maintenance

Michael Coulson | March 12, 2025

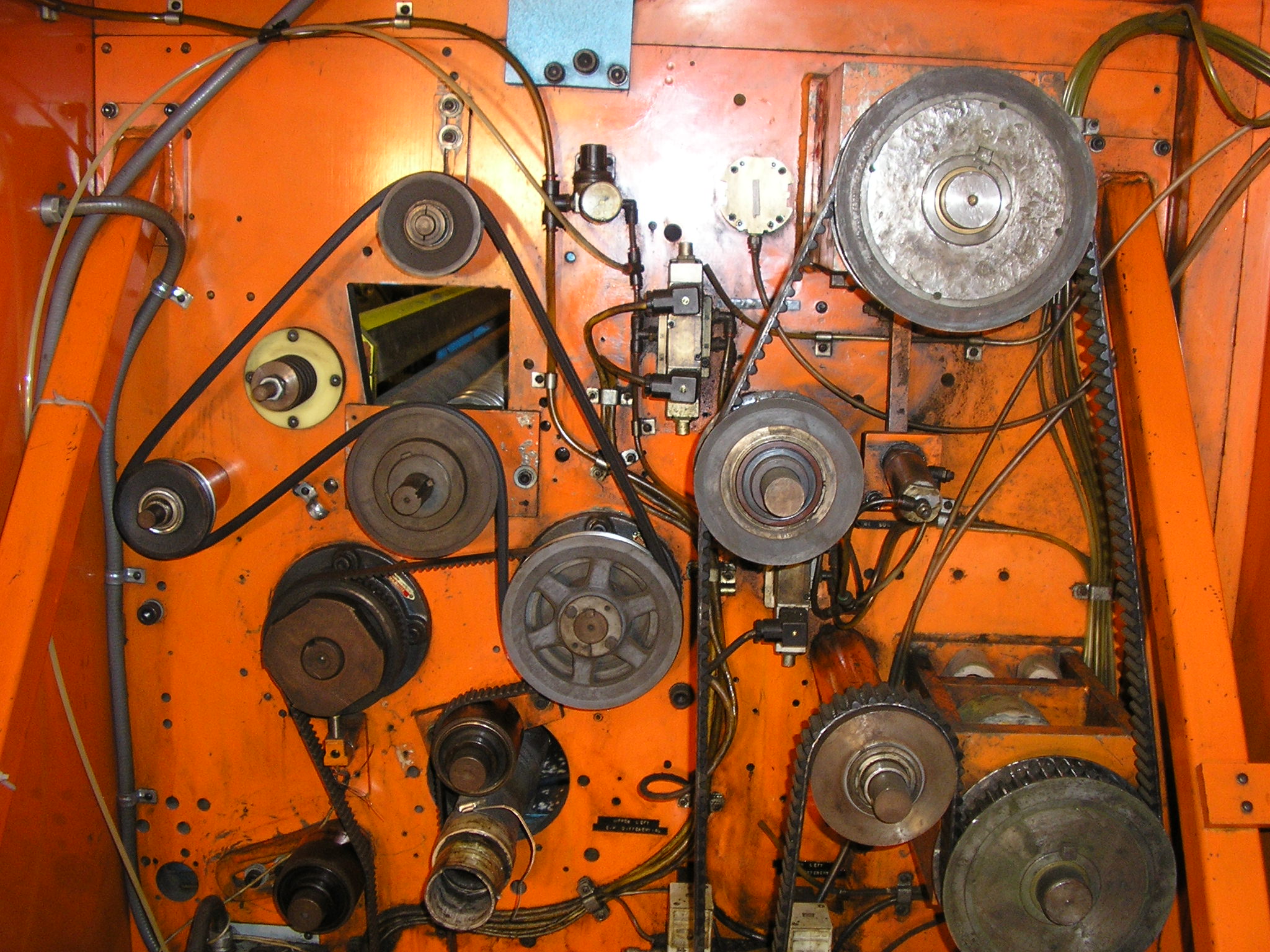

Proper slitter rewinder maintenance is essential for ensuring long-term performance, minimizing downtime, and maintaining high-quality output. Neglecting regular upkeep can lead to costly repairs, production delays, and reduced efficiency. This guide will provide essential maintenance practices, troubleshooting tips, and insights into machine rebuilding services to keep your converting equipment in optimal condition.

Why Slitter Rewinder Maintenance Matters

A well-maintained slitter rewinder machine ensures consistent performance, reduces material waste, and extends the lifespan of your web handling equipment. Whether you own a new slitter rewinder or a used slitter rewinder, investing in routine maintenance can prevent unexpected breakdowns and expensive repairs.Essential Slitter Rewinder Maintenance Practices

Always perform LOTO procedure prior to Servicing1. Regular Inspection and Cleaning

- Inspect shear slitters, score slitters, and razor slitters for signs of wear.

- Clean mandrels and rollers for wear and buildup or contamination.

- Check transmission components for wear to ensure that all moving parts are free of debris and properly lubricated.

- Check pneumatic and hydraulic features for leaks and proper operation.

- Make sure all Safety features are operational and all guarding is secure.

2. Blade and Anvil Maintenance

- Replace dull razor slitters, shear slitters and score slitters to maintain precision cutting.

- Check anvil rolls for damage and replace as needed.

- Align blades correctly to prevent uneven cuts and material waste.

- Check for proper operation.

3. Tension and Web Alignment Checks

- Regularly check the tension control systems to ensure proper material handling.

- Check roller alignment throughout the system from the unwind machine to the Slitter Rewinder to prevent misalignment issues.

- Verify that the Slitter Rewinder is operating smoothly.

4. Lubrication and Component Replacement

- Apply lubricants to bearings, chains, and rollers as per the manufacturer’s guidelines.

- Inspect belts and motors for wear and replace them before failure occurs.

- Keep a stock of essential web handling equipment parts for quick replacements.

5. Calibration and Software Updates

- Ensure your Tension Control systems are properly calibrated.

- Update software to optimize efficiency and reduce manual errors.

- Test automation systems regularly to prevent performance issues.

Troubleshooting Common Slitter Rewinder Issues

Issue: Uneven Slitting

- Check blade sharpness and replace dull blades.

- Verify blade alignment and adjust as needed.

- Inspect material tension settings for inconsistencies.

Issue: Material Wrinkles or Misalignment

- Adjust web tension settings on your Slitter Rewinder.

- Ensure rollers are properly aligned and clean.

- Check for loose or worn-out drive components.

Issue: Excessive Dust or Material Build-up

- Clean slitting components regularly.

- Use anti-static systems if dealing with static issues.

- Check the pneumatic system and components for contamination.

The Role of Machine Rebuilding Services

If your Slitter Rewinder is experiencing frequent breakdowns, investing in machine rebuilding services can restore its performance and extend its operational life. Converting equipment repair specialists can:- Replace worn-out components.

- Upgrade outdated control systems.

- Improve machine efficiency through precision tuning.

- Add current upgrades and features

Conclusion

Routine slitter rewinder maintenance is the key to ensuring smooth operation, reducing downtime, and extending equipment life. Whether you need converting equipment repair, web handling equipment parts, or a complete machine rebuilding service, staying proactive with maintenance will keep your production running at peak efficiency. Looking for professional slitter rewinder maintenance or machine rebuilding services? Contact us today to ensure your converting equipment stays in top condition!Recent Post

-

Engineering High-Efficiency Converting with Surface Winders

Michael Coulson | May 27, 2025

-

Choosing the Right Surface Winder for Your Business

Michael Coulson | May 20, 2025

-

The Evolution of Surface Winders in Converting Applications

Michael Coulson | May 14, 2025

-

Solving the Machinery Maintenance Crisis—With Phoenix Machine

Michael Coulson | May 1, 2025

-

How to Choose the Right Slitter Rewinder for Your Business

Michael Coulson | March 19, 2025

Newsletter

Get Latest News and Updates From Marketer Enter Your Email Address